1. The Hidden Indicators Behind a Reliable Shisha Charcoal Factory

bintangbriquettes.com – When doing a Shisha Charcoal Factory Comparison, most buyers usually look at the obvious parts—machine size, production capacity, sample quality, or price per carton. But the truth is this: the most reliable factories are not identified by what you see on the surface, but by the behavior patterns that appear long before mass production begins.

A factory may send a perfect sample, yet fail completely during bulk production. Another factory may not have the most impressive photos, yet consistently delivers stable quality for years. The difference comes from subtle operational signals—signals that reveal whether the factory has structure, discipline, and long-term reliability behind the scenes.

Below are the hidden indicators that truly show whether a factory can be trusted for long-term cooperation.

1.1 Communication Style: The First Window Into Factory Reliability

A factory’s communication style often reflects how well their internal system works.

✔ Clear and detailed answers

Factories with strong internal processes tend to give specific and structured explanations when asked about ash content, carbonization, moisture percentage, density, or lead time management.

✔ Vague or generic responses

If a factory keeps replying with:

- “Don’t worry, we can do it,”

- “Our quality is good,”

- “Same as the sample,”

without giving real data, this is a sign of weak internal control.

Such factories often struggle to maintain consistent quality once orders increase.

In a professional Shisha Charcoal Factory Comparison, this indicator is extremely valuable because it predicts future problems before they happen.

1.2 Transparency When Discussing Challenges

Reliable factories do not pretend to be perfect.

They openly explain challenges like:

- rainy-season drying delays,

- temporary shell supply fluctuations,

- kiln maintenance,

- changes in binder material.

This honesty may sound like a weakness, but in reality, it’s a strong sign of reliability.

Factories that hide problems usually deliver unpredictable quality, while transparent factories tend to deliver stable results because they manage issues systematically.

1.3 Consistency in Response Time

Factories with strong management show consistency in how fast and how clearly they reply—even during busy seasons.

A reliable factory:

- replies at similar times each day,

- gives structured updates,

- provides production photos without being asked.

An unreliable one usually responds only when they have “good news” and disappears when issues appear.

In the context of a Shisha Charcoal Factory Comparison, this is one of the strongest early indicators of long-term trustworthiness.

1.4 How They Handle Technical Questions

A professional, export-ready factory enjoys discussing details because they understand their craft.

When you ask about:

- ash percentage variations,

- carbonization temperature control,

- briquette density,

- pressure rating,

a reliable factory gives real explanations rather than avoiding the topic.

The depth of their explanation shows:

- How well they control their process

- How mature their production system is

- How stable their product will be in mass production

This is one of the clearest hidden indicators during a Shisha Charcoal Factory Comparison.

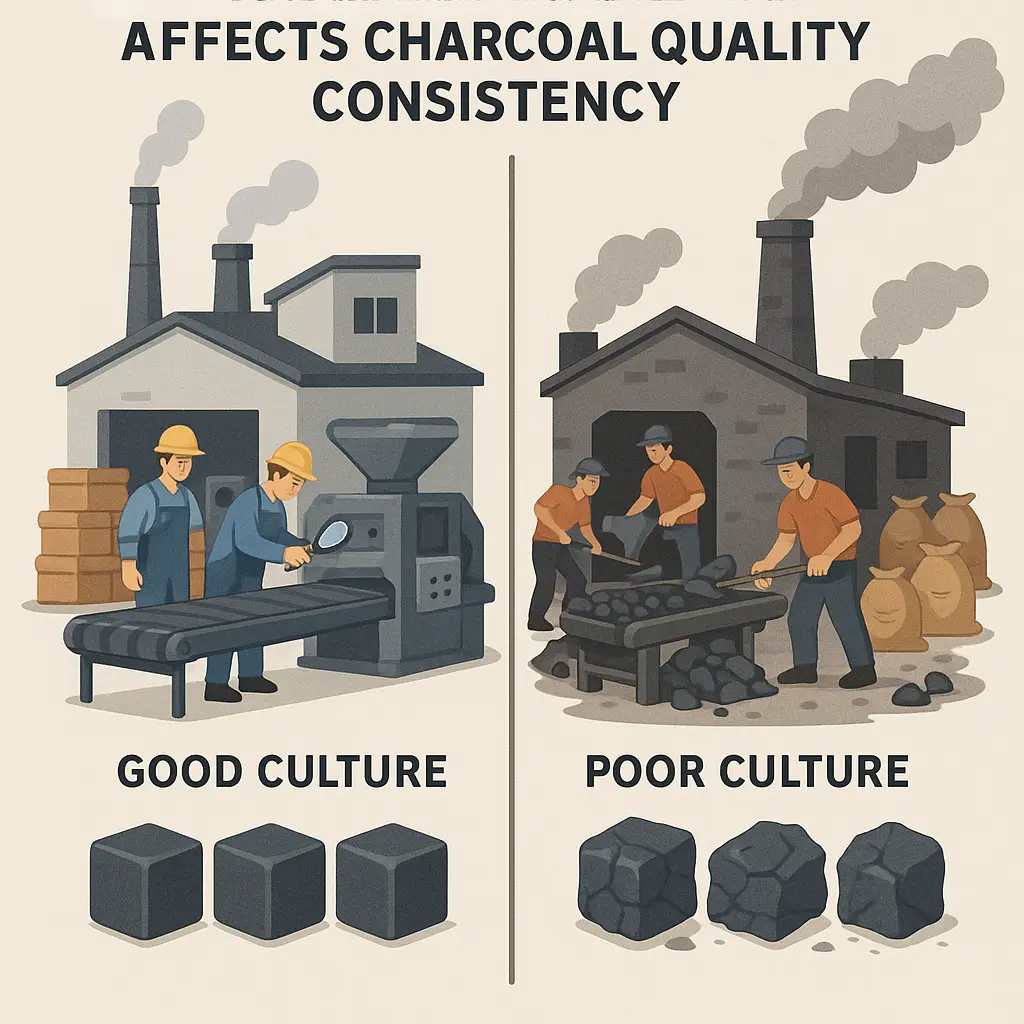

2. How Factory Culture Affects Charcoal Quality Consistency

Most discussions about shisha charcoal quality focus only on machines, materials, or specifications. But in a deeper Shisha Charcoal Factory Comparison, one of the most overlooked elements is factory culture—the habits, discipline, and work ethic of the people behind the production.

Two factories may use the same type of coconut shell, the same hydraulic press, and even follow the same recipe. Yet one factory consistently delivers perfect briquettes, while the other produces unstable batches that vary from month to month.

The difference comes from how the factory operates as a team.

2.1 Discipline in Daily Operations Shapes Final Quality

In factories with strong discipline, workers follow routines with precision:

- Carbonization workers check temperature ranges regularly.

- Mixing teams follow exact ratios, not rough estimates.

- Pressing crews calibrate machines before each shift.

- Quality control staff run tests at fixed intervals, not “when they remember.”

This disciplined culture creates briquettes with:

- stable ash,

- consistent density,

- predictable burning time,

- and fewer breakages.

In a Shisha Charcoal Factory Comparison, this discipline is what separates a smooth, reliable supplier from one that sends unstable quality over time.

2.2 Experience and Skill of Operators Matter More Than Machines

Many buyers assume that newer machines automatically produce better briquettes. In reality, skilled operators often matter more than the equipment itself.

Experienced workers know how to:

- adjust pressure when shell moisture changes,

- balance binder usage,

- detect mixing inconsistencies by sight and feel,

- maintain kiln heat evenly during carbonization.

Factories with high staff turnover usually struggle with consistency because new workers don’t yet understand the “feel” of the material.

This is why two factories with identical technology can deliver completely different results.

Skill and experience create stability—something essential to highlight in any Shisha Charcoal Factory Comparison.

2.3 Internal Communication Reflects Organizational Strength

In strong factories, departments communicate smoothly.

When carbonization teams update moisture levels, the mixing team adjusts ratios.

When the QC team finds cracks, the pressing team recalibrates pressure immediately.

Factories with poor internal communication often produce inconsistent batches because departments work like separate islands instead of a unified system.

The result?

Stable quality in one shipment… unpredictable issues in the next.

2.4 A Problem-Solving Culture vs. a Blame-Avoiding Culture

This difference is crucial.

✔ Reliable factories

Identify problems early, fix them quickly, and prevent them from spreading into the final product.

Their team collaborates to solve issues.

✘ Unreliable factories

Ignore small issues until they become major production defects.

Workers avoid responsibility, and management reacts too late.

This internal behavior directly affects burning performance, ash color, hardness, and packaging quality.

It’s a hidden but powerful aspect of every Shisha Charcoal Factory Comparison.

3. Supply Stability: The Most Overlooked Part of Factory Comparison

When conducting a Shisha Charcoal Factory Comparison, many buyers focus heavily on sample quality—but overlook one of the most critical factors: supply stability.

A factory may produce excellent charcoal today, but can they maintain the same quality and volume next month, during rainy season, or when demand suddenly spikes?

The answer depends not only on machines or recipes, but on how well the factory manages its raw materials, warehouse, and overall supply chain.

This area is rarely discussed publicly, yet it is often the biggest difference between a reliable and an unreliable shisha charcoal factory.

3.1 Coconut Shell Availability Changes Throughout the Year

Coconut shell is a natural resource, meaning its availability fluctuates due to:

- Seasonal rainfall

- Harvest cycles

- Regional supply variations

- Competition between factories

A factory with strong planning will secure its shell supply months ahead, even storing extra inventory for peak production periods.

A weaker factory will scramble for materials at the last minute, causing:

- inconsistent carbonization quality,

- unstable ash content,

- variations in density and burn duration.

In a professional Shisha Charcoal Factory Comparison, this difference alone can determine whether the factory will remain consistent from shipment to shipment.

3.2 Moisture Management: The Silent Killer of Consistency

Coconut shells absorb moisture easily, especially during humid or rainy weather.

Factories that fail to manage moisture correctly often produce briquettes that:

- crack easily,

- burn unevenly,

- generate more smoke,

- or lose heat performance.

Reliable factories use controlled storage methods such as:

- elevated racks,

- airflow-controlled warehouses,

- pre-drying routines,

- moisture checks before carbonization.

This results in stable charcoal performance, regardless of weather conditions.

Poorly managed factories rely too much on sun-drying and guesswork, making their output unstable.

3.3 Warehouse Organization Shows Production Maturity

Buyers rarely ask about the warehouse, yet it reveals so much about factory reliability.

Factories with organized storage:

- separate raw shells, carbonized shells, ready-mix materials, and finished briquettes,

- implement FIFO (First In, First Out),

- protect materials from humidity, pests, and contamination.

Factories with chaotic storage:

- mix materials together,

- lose track of which shells are fresh or old,

- expose charcoal to moisture,

- or use materials inconsistently depending on what’s available.

The warehouse condition directly impacts final product consistency—and is a critical point in a Shisha Charcoal Factory Comparison.

3.4 Supplier Relationships Determine Long-Term Stability

Some factories rely on random shell collectors with no long-term contracts.

Others build strong relationships with local coconut suppliers to secure steady supply.

Factories with reliable upstream relationships can guarantee:

- consistent quality of shells,

- predictable carbon content,

- smoother production scheduling,

- fewer delays.

Factories without stable suppliers often experience interruptions, forcing them to switch materials—resulting in noticeable quality changes from batch to batch.

3.5 Ability to Handle Sudden Volume Spikes

A factory is truly tested when demand increases, such as during:

- Ramadan,

- European summer season,

- New market openings,

- Unexpected large orders.

A reliable factory already prepares extra raw materials and increases kiln rotation ahead of these periods.

An unprepared factory will either:

- delay production,

- compromise quality, or

- split focus among buyers, reducing consistency.

This factor is rarely discussed online but is essential in any real-world Shisha Charcoal Factory Comparison, especially for long-term importers.

4. The Reliability Pattern: How Factories Behave During High-Demand Seasons

One of the most revealing parts of any Shisha Charcoal Factory Comparison is how factories behave during high-demand seasons.

Anyone can deliver good quality when production is slow.

But the real test happens when:

- Ramadan orders surge

- Summer BBQ season increases demand in Europe

- Gulf countries request urgent restocks

- Multiple buyers submit orders at the same time

This is where the difference between a stable, well-managed factory and an unpredictable factory becomes very clear.

4.1 Do They Maintain Quality When Orders Increase?

Reliable factories treat quality as a constant—not something that changes based on production pressure.

A stable factory will:

- maintain the same formula even when rushing,

- increase QC checks during high volume,

- keep ash and moisture levels consistent,

- avoid using alternative shells or binders under pressure.

An unreliable factory will:

- reduce drying time,

- change pressure settings,

- mix shells of different carbonization levels,

- push quantity over quality.

This is why many buyers receive “perfect samples” but inconsistent mass production.

The issue usually appears during peak season.

Including this observation in your Shisha Charcoal Factory Comparison helps you identify factories that can handle growth without sacrificing quality.

4.2 How Factories Prioritize Long-Term Buyers vs New Buyers

During a busy season, factories must decide whom they prioritize.

Reliable factories:

- honor existing buyer schedules,

- maintain realistic timelines,

- do not overpromise to new buyers,

- stay transparent about capacity.

Unreliable factories:

- accept too many orders,

- prioritize buyers who pay first rather than those with contracts,

- push old clients aside to chase new deals,

- create delays and quality drops across the board.

This behavior clearly separates short-term factories from those capable of stable export operations.

4.3 Lead Time Stability Is a Major Reliability Signal

Many factories promise a 15–20 day lead time.

But the real indicator is whether they can maintain that timeline when:

- rain affects drying,

- fuel prices rise,

- shell supply tightens,

- machines require maintenance.

A factory with mature planning adjusts workloads smoothly and keeps delays minimal.

A weaker factory collapses under pressure, causing:

- shipment delays,

- moisture issues,

- rushed carbonization,

- inconsistent briquette hardness.

This is why lead time behavior is one of the most important factors in a Shisha Charcoal Factory Comparison, even more than price.

4.4 Production Transparency During Busy Months

Factories that stay transparent during peak season are the most trustworthy.

They provide:

- warehouse photos,

- kiln rotation updates,

- loading schedules,

- real production timelines.

Unreliable factories go silent during busy times, replying only when they have “good news.”

This silence often means they are overwhelmed or compromising quality.

4.5 Do They Increase Workforce and Kiln Rotation?

Factories that plan well will:

- hire additional seasonal workers,

- prepare extra carbonized shell inventory,

- run kilns in rotating shifts,

- expand the drying area temporarily.

Factories that fail to prepare will produce charcoal that:

- cracks easily,

- burns too fast,

- contains unstable ash,

- arrives with moisture problems.

These issues typically appear only during peak season—making this an essential point in a thoughtful Shisha Charcoal Factory Comparison.

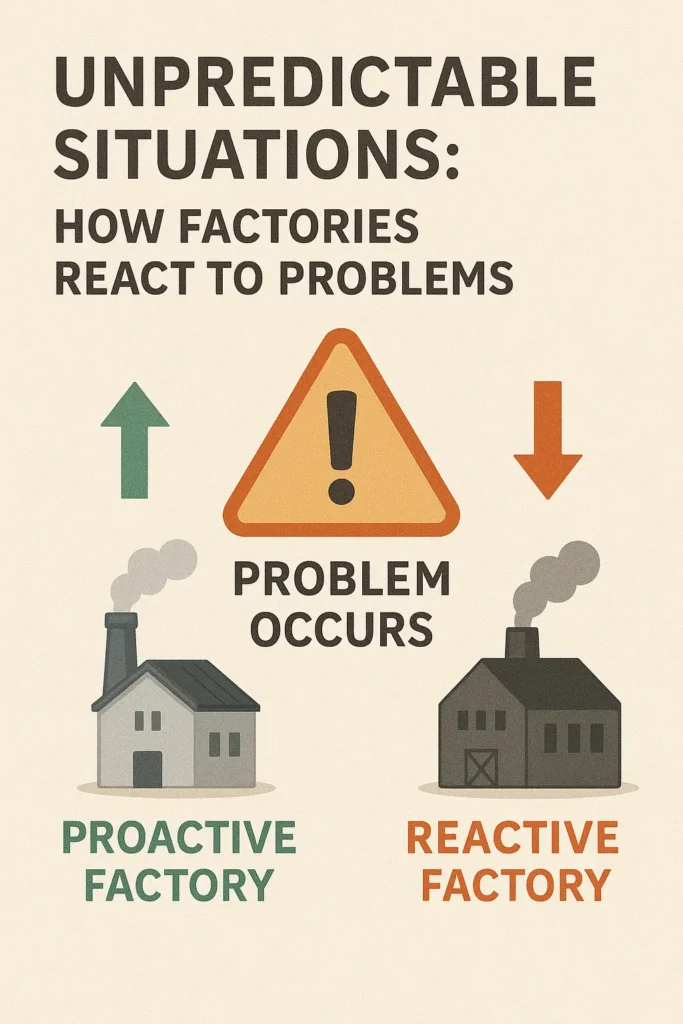

5. Unpredictable Situations: How Factories React to Problems

In any Shisha Charcoal Factory Comparison, the ability of a factory to respond to unexpected problems is a critical—but often overlooked—indicator of reliability.

Every factory faces challenges: machines break down, shell deliveries are delayed, weather conditions change, or urgent orders appear. The difference between a dependable factory and an unreliable one is how they handle these unpredictable situations.

5.1 Equipment Failures and Maintenance

Even top-tier factories can experience mechanical failures.

A reliable factory will:

- have backup machines or kilns ready,

- maintain a regular maintenance schedule,

- communicate clearly about the expected downtime,

- implement quick solutions without sacrificing quality.

An unreliable factory may:

- delay production until the broken machine is repaired,

- rush batches once the machine is fixed,

- compromise quality, or

- hide the issue from buyers until shipment.

The way a factory handles equipment problems speaks volumes about its long-term consistency, making it an essential part of any Shisha Charcoal Factory Comparison.

5.2 Raw Material Shortages

Coconut shell supply can be disrupted by:

- poor harvesting seasons,

- logistics delays,

- sudden spikes in market demand.

Reliable factories anticipate shortages by maintaining:

- safety stock,

- multiple supplier agreements,

- flexible schedules.

Factories that do not plan for shortages may substitute lower-quality shells, skip pre-drying, or reduce carbonization time—resulting in inconsistent briquette performance.

5.3 Weather and Environmental Challenges

Factories that rely on sun-drying or poorly controlled warehouses are vulnerable to rain, humidity, or extreme heat.

A factory that handles environmental challenges well will:

- move drying indoors or use ovens,

- adjust carbonization schedules,

- monitor moisture content constantly.

Factories that ignore environmental impacts often produce charcoal that cracks, burns unevenly, or has high ash content.

5.4 Order Surges and Customer Pressure

Unexpected large orders can reveal a factory’s true capabilities:

- Can they scale production without sacrificing quality?

- Do they communicate delays proactively?

- Can they prioritize correctly without overpromising?

Factories with strong operational systems handle surges smoothly, while weaker factories may rush batches, skip QC checks, or miss deadlines—risking shipment rejection.

5.5 Transparency During Problem Solving

The best factories communicate clearly and honestly when issues arise. They provide:

- Updates with photos or videos,

- Adjusted timelines,

- Suggested solutions or alternatives,

- Honest explanations without blaming the buyer.

Unreliable factories hide issues, giving vague responses or ignoring messages. Observing this behavior is one of the most effective ways to judge reliability in a Shisha Charcoal Factory Comparison.

If you like, I can now move to Bagian 6: Decision Guide: How Importers Can Read Factory Signals Before Ordering, finishing the article with actionable takeaways for buyers.

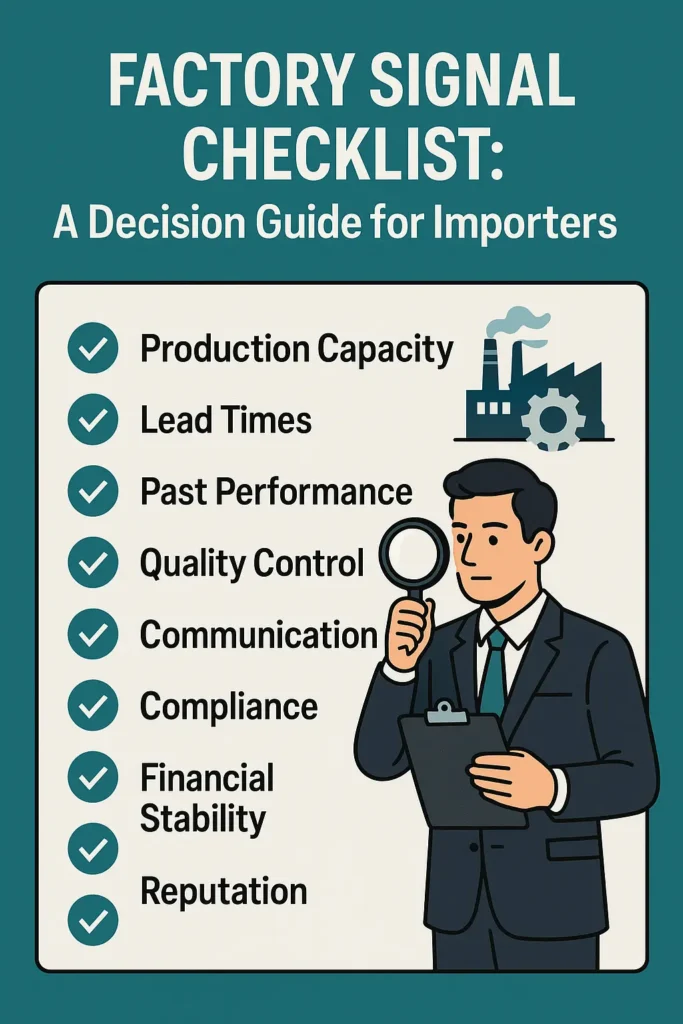

6. Decision Guide: How Importers Can Read Factory Signals Before Ordering

After exploring hidden indicators, factory culture, supply stability, behavior during peak season, and problem-solving ability, the final step in any Shisha Charcoal Factory Comparison is learning how to read these signals effectively before placing an order.

This guide is designed to help importers make informed decisions and avoid common pitfalls when choosing a reliable shisha charcoal factory.

6.1 Evaluate Communication Patterns

- Check how quickly and consistently the factory responds.

- Assess clarity: are answers specific or vague?

- Observe transparency: do they openly discuss challenges?

Tip: A factory that communicates clearly even during peak season or unexpected issues is usually more reliable in the long term.

6.2 Ask About Supply Management

- How do they secure raw materials?

- Do they maintain extra stock for high-demand periods?

- How do they handle seasonal fluctuations?

Factories that proactively manage supply are more likely to deliver consistent quality across multiple shipments.

6.3 Test Problem-Solving Capability

- Present hypothetical issues: delayed shell supply, kiln maintenance, or rush orders.

- Note how they respond—do they offer practical solutions?

- Evaluate if they admit challenges honestly or avoid the topic.

A factory’s reaction is often a better predictor of reliability than past production samples.

6.4 Check Internal Organization and Culture

- Ask about staff experience and training.

- Learn how departments coordinate: production, QC, and logistics.

- Evaluate whether the factory emphasizes consistency over speed.

Factories with strong internal culture produce more predictable results, even during unforeseen problems.

6.5 Review Documentation and Certifications

- Certificates such as Halal, ISO, MSDS, and SGS tests show export readiness.

- Clear documentation of processes, weight, and packaging is a sign of professional management.

- Legal compliance reduces the risk of delays at customs.

In a Shisha Charcoal Factory Comparison, verified certifications and documentation are crucial for long-term trust.

6.6 Observe Historical Consistency

- Ask for references or shipment histories.

- Look at previous buyers’ experiences: have quality or timing issues occurred?

- Compare multiple batches to see if results remain consistent.

Consistency over time is often the single most reliable indicator of a factory’s credibility.

6.7 Make an Objective Decision

After gathering all information:

- Compare factories side by side, not just by price or sample quality.

- Consider hidden indicators: culture, communication, problem-solving, supply stability.

- Choose the factory that balances quality, reliability, transparency, and consistency.

By following this approach, importers can confidently select a partner that will deliver stable, high-quality shisha charcoal shipment after shipment.